Mastering the Art of Impeller Selection for Submersible Waste Water Pumps

Category : Energy Efficient Pumps , Waste Water Pumps

Introduction:

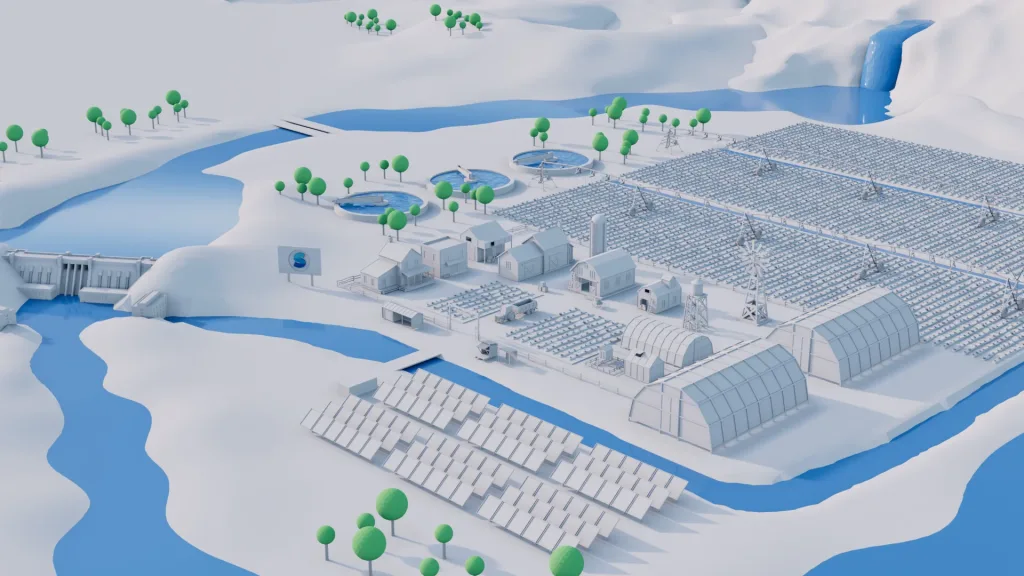

In the realm of wastewater management, the selection of the right impeller type for waste water submersible pumps is crucial for efficient operation and long-term reliability. Impellers come in various designs, each tailored to handle specific challenges posed by wastewater composition, including solids content, fibrous substances, and the risk of clogging. In this guide, we’ll explore different impeller types and how to choose the best one for your wastewater pumping needs.

Understanding Impeller Types: Impellers are the heart of submersible pumps, responsible for generating the flow and pressure required to move wastewater effectively. Here are some common impeller types and their key characteristics:

- Anti-Clogging Vortex Impellers:

- Designed to handle wastewater with high solids content and minimize the risk of clogging.

- Features a vortex design that allows solids to pass through without interference, reducing the likelihood of blockages.

- Ideal for applications where clogging is a significant concern, such as sewage pumping stations and industrial wastewater treatment plants.

- Multi-Channel Propeller Open Impeller:

- Suited for pumping charged liquids containing fibrous substances or suspended solids.

- Features multiple channels and an open design to facilitate the passage of solids and fibrous materials without clogging.

- Provides efficient pumping performance in applications where traditional impeller designs may struggle with fibrous content.

- Multi-Channel Open Impeller with Helical Channel Wear Disc:

- Combines the benefits of a multi-channel design with the addition of a helical wear disc to minimize wear and prolong impeller life.

- Offers enhanced resistance to abrasion and erosion, making it suitable for applications with abrasive or corrosive wastewater.

- Closed Impeller:

- Engineered for top efficiency in pumping charged liquids with low fibrous content.

- Features a closed design with tightly spaced vanes to maximize hydraulic efficiency and minimize recirculation losses.

- Ideal for applications where energy efficiency is paramount and clogging is less of a concern.

Anti clogging vortex impellers.

Multi-channel propeller open impeller to pump charged liquids, ideal for fibrous substances.

Multi-channel open impeller with helical channel wear disc. Minimized risk of clogging.

Closed impeller for top efficiency in pumping charged liquids with low fibrous substances.

Key Considerations for Impeller Selection: When choosing the right impeller type for your submersible wastewater pump, consider the following factors:

- Wastewater Composition:

- Assess the characteristics of the wastewater, including solids content, fibrous substances, and the risk of clogging.

- Select an impeller type that is specifically designed to handle the challenges posed by your wastewater composition.

- Pumping Efficiency:

- Consider the desired pumping efficiency and energy consumption of the system.

- Choose an impeller design that balances hydraulic performance with energy efficiency, taking into account the specific operating conditions and requirements of your application.

- Wear Resistance:

- Evaluate the potential for wear and abrasion in the pump system.

- Opt for impellers constructed from durable materials and featuring wear-resistant coatings or enhancements to prolong service life and minimize maintenance requirements.

- Application-Specific Requirements:

- Take into account any unique requirements or constraints of your application, such as flow rate, head pressure, and operating conditions.

- Consult with pump manufacturers or experts to ensure the selected impeller type is well-suited to meet the demands of your wastewater pumping system.

Conclusion:

Choosing the right impeller type for your submersible wastewater pump is essential for achieving efficient operation, minimizing downtime, and maximizing the lifespan of your equipment. By understanding the characteristics and capabilities of different impeller designs and considering factors such as wastewater composition, pumping efficiency, wear resistance, and application-specific requirements, you can make an informed decision that ensures optimal performance and reliability of your wastewater management system. Remember, investing in the appropriate impeller upfront can lead to significant long-term savings and operational benefits.